Wettability of GP Materials

By Martin Conway

Wettability

Wettability is a measure of the tendency of a solution to spread over a surface.

The wetting angle is a measure of how wettable a given surface is. The steeper the angle the more the surface is resisting the spread of the solution across its surface and thereore the less wettable that surface is said to be.

Methods of measurement

Visually the easiest way to represent this phenomenon is called the Sessile Drop method. As the name suggests, a drop of liquid it sat upon a sample of material. The angle that the droplet forms can be measured, and a comparison between the performances of different materials made. The problem with this method is that the surrounding atmosphere can affect the outcome. In a humid environment the surface to be tested can be “preconditioned “by the presence of moisture in the surrounding air.

The Captive Bubble technique uses the same equipment, but a bubble of air is introduced into the underside of a block of the material to be tested which has been immersed in water. This means that the ambient atmosphere does not affect the system.

In both of these methods the liquid/air is introduce via a syringe apparatus which can be controlled. The bubble can be enlarged with the addition of more liquid/air. This gives an “advancing angle”. It can also be withdrawn, and this is called the “receding angle”.

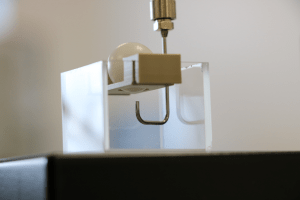

Equipment set up to introduce a captive bubble under a sample of material

In contact lens materials, the advancing angle is an indication of what happens as the lid moves across the surface of the lens during the blink.

The receding angle indicates how stable the tear film is likely to be after the blink, and is therefore probably more indicative of how the lens is likely to be perceived by the wearer.

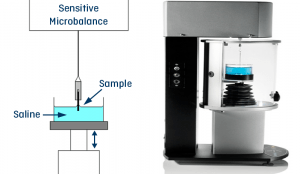

The Wilhemy Plate method is a much more complex method using a very sensitive microbalance. A strip of material to be tested is slowly lowered into saline and then removed. The microbalance records the force resisting the entry of the material into the liquid as well as the force resisting its removal. The advantage of this method is that it removes the operator error involved in assessing the angular measurements required in the previous two methods.

Wilhemy Plate equipment with diagram to demonstrate technique

Wettability of GP contact lens materials

The wettability of a gas permeable material is one of the key factors governing the performance of a lens on eye and along with permeability, will influence a practitioner’s choice of a particular material. Manufacturers quote the wetting angle of a given material as measured at 7 days after soaking for a good reason. Prior to that, the wetting angle is much higher than the figure that is achieved after the surface of the lens has had a chance to become fully conditioned.

A modern GP polymer may contain polymer chains consisting of as many as ten different monomers. Some of those are hydrophobic (such as the silicone-containing monomers) and some are hydrophilic.

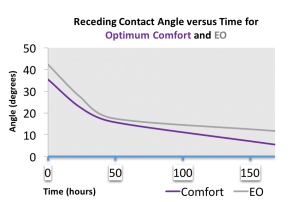

When a lens is first lathed, the surface will be made up from a randomly arranged selection of hydrophobic and hydrophilic elements. Over the 7 days of soaking, the presence of the wetting solution against the surface of the lens will attract more hydrophilic monomer to the surface and at the same time, repel hydrophobic monomers. It is this ability of the monomers to rotate about the axis of the polymer chain that causes the surface to change. As can be seen in the above graph, most of this change occurs within the first 48 hours and then gradually continues until the ultimate wettability is achieved after 7 days.

Graph demonstrates the rapid reduction in wetting angle over first 48 hours of soaking, and then achieving maximum wettability at 7 days

Laboratories should always ship GP lenses in wetting solutions. This allows the lenses to partially condition during transit so that, when the patient receives the lenses, they are more wettable and therefore more comfortable than if they were shipped dry. Ideally the lenses should sit in the wetting solution for the full week to allow complete conditioning to take place, but not many patients in this day and age are prepared to wait that long!

Many practitioners will have received the comment from patients that their new lenses are not as comfortable as the old pair. The same patients will later state that there new lenses improved over the following week!

Wet lens surfaces make it difficult for deposits to attach to the surface. During this first period of wear, it is important that the patient is instructed to clean their lens at the end of each wearing period to remove any lipid that may have accumulated on the surface. New wearers are more likely to be compliant, but existing wearers may have become lax with their cleaning routine and have got away with it with their old, wet, fully conditioned lenses. If lipids are allowed to accumulate and are not removed at the end of each day’s wear, then the process of conditioning can be reversed. The patient may return with the lipid on the lens, which you can see under the slit lamp. It is easily removed with a surfactant, but what remains is the dry spot on the lens caused by the presence of the lipid. The lipid, which is hydrophobic, has displaced the hydrophilic monomer at the surface and attracted hydrophobic monomer to replace it. The patient wears the lens and lo and behold, the grease spot re-appears! Lipid from the tears now adheres to the dry spot where previously it would have found a wetted surface.

Many perfectly sound lenses have found their way back to labs as a complaint for surface quality for this reason alone. The irony is, that the practitioner cleans the lens and sends it back to the lab in a container with wetting solution. When the lab receives the lens the dry spot has disappeared!

Martin Conway has over 40 years’ experience in the contact lens field as a qualified Contact Lens Optician. He is registered with the UK General Optical Council on the Speciality Contact Lens Register. Martin is a fellow of the British Contact Lens Association (FBCLA), and The International Association of Contact Lens Educators (FIACLE). He has served in the Professional Services role as an educator and clinical adviser on behalf of both Sauflon and CIBA, and now acts as Professional Services Consultant for Contamac. Martin has lectured extensively in Europe, Asia, Russia, North and South America and the Middle East.

More articles by Martin Conway: