Gareth Browne – Technical & Quality Control Manager

Please describe your role at Contamac:

My role has continually evolved during my 19 years at Contamac. I am Technical & Quality Control Manager. My main responsibility is to oversee the testing of our materials to ensure they meet our specifications and the expectations of our customers. We have a fully operational contact lens laboratory at our facility, where we replicate the typical manufacturing processes our customers use to test all of our materials.

I am also Technical Advisor for Contamac, this role primarily is offering support to our customers. This support may be required when we are introducing a new material to the market place that requires new manufacturing guidance. I also assist our customers across the world with any processing issues they may be experiencing with our materials.

Another aspect of my job includes working closely with our R&D department on bringing new contact lens and IOL materials to the market place. We are always looking at ways of improving the materials we provide our customers and ultimately the patient. This can also be the most exciting and challenging part of my role at Contamac.

What is your professional history?

It was only by luck that I found my way into this industry. When I was 16, I joined Cambridge Precision Limited straight from college as a trainee contact lens technician. My first experience in contact lens manufacture came with using manual Nissel and City Crown lathes. This is where I really gained experience and understanding of the making of contact lenses, as you generated a finished lens totally with your own hands. We worked closely with numerous major eye clinics in hospitals throughout the UK, we specialised in paediatric soft lenses.

After 10 years of working at Cambridge Precision I then worked for CLPL. Again, I was lucky as this laboratory happened to be in the village in which I grew up, and I had recently moved back to with my young family. At CLPL I gained my first experience with using CNC lathes, which was a massive step up in technology. At both companies, I learnt how to produce both GP and hydrogel prescription lenses in materials from all the different polymer suppliers, including Contamac. After 4 really enjoyable years in which I learnt so much about CNC lathing and different manufacturing methods, I left to join Contamac in 2001.

What do you enjoy most about working at Contamac and our industry?

It’s the people at Contamac that makes it such a special place to work. I have been here since 2001 and have seen it grow quite considerably over the years but it still has the same family feeling. After working in this industry for 33 years I still look forward to coming to work every day, as I never know exactly what I’ll be doing or who I will be in contact with from across the world.

I am very fortunate to have such a diverse role within the company. My position at Contamac has given me the opportunity to visit over 100 laboratories all over the world. Sometimes I visit labs to help them overcome an issue they may be experiencing with a specific material or if they are having general manufacturing problems. It is always great when you resolve an issue and help the customer improve their processes. Being able to assist and help our customers is probably the most satisfying part of my job. However, the best part of my job when visiting these labs is meeting new people and creating new friendships.

One of the most interesting parts of my job is working on the development of new materials with our in house R&D team. I have worked on a number of major projects in my 19 years at Contamac. My first major project with the R&D team was developing and bringing the Optimum range of materials to the market. It seems like a long time since we launched this product, but it is one I am particularly proud of, as it is still gaining market share every year.

I was heavily involved in the development of the first latheable silicone hydrogel to be made available to custom soft laboratories across the world. This was probably the most challenging project I have ever worked on and one in which I learnt so much about how silicone hydrogels differed from the conventional hydrogels I was so used to.

Since joining Contamac, I have had the opportunity to attend and represent our company at many different trade shows. This is probably one of my favourite aspects my position has allowed me to do over the past 19 years. These exhibitions are fantastic for meeting all your customers, suppliers and competitors in one place. I have attended EFCLIN practically every year since I joined Contamac and I’m very proud to now be a representative on the board. Admittedly, I didn’t realise how much work was involved in being a board member. It has given me a greater appreciation for those who contribute to this organisation. It was a great shame that we had to postpone this year’s event due to COVID-19 but I am confident next year’s event will be very successful.

You’ve been working with lathes for 33 years, have you ever made anything that pushed their capabilities and your interest?

I particularly enjoyed working on a project for one of the most well-known breweries in the world. This beer producer was looking at making their product more appealing to a younger market and needed the ability to pull a quicker pint of beer. To do this, they needed a hydrogel polymer to act as a conductor between the glass and the ultrasonic plate. That is where we came in. It was our job to find out the best water content material for this application. I had to produce discs on our CNC lathes that were approximately 6 times larger than a typical contact lens. Although very challenging, it was also extremely rewarding, as I was chief beer tester.

From making very large devices, we have also worked on many projects that required producing items that were extremely small compared to a conventional contact lens. We have worked on many projects with ophthalmologists and with Universities from around the world that have come up with innovative ideas for new corneal devices for treating many eye conditions.

One project in particular that I found interesting but also by far one of the most challenging involved making the smallest lens I have ever had to manufacture. The lens was 4mm in diameter and only 40 microns thick, with a 1.8mm central hole. To make it even more challenging, these were made in a high water content hydrogel material. So in their dry state, the lenses were even thinner and exceptionally difficult to handle. The lenses were so thin that we had to turn off the air conditioning unit in the laboratory, as it would blow the lenses away and they were lost forever. We can only make such lenses with extremely high precision CNC lathes we now have at our disposal.

If you were shipwrecked on a deserted island, but all your human needs—such as food and water—were taken care of, what two items would you want to have with you?

Without any hesitation, it would be my wife I would take with me, as she’s the only thing in my life I couldn’t do without. We, like many people, have had our holiday cancelled this year due to COVID-19. So I couldn’t go on holiday without her, as I would also be in trouble!

The second item is far more difficult to choose. It would have to be a good book. I would take the Tolkien collection of books to read. As the Lord of the Rings series is probably my favourite films of all time.

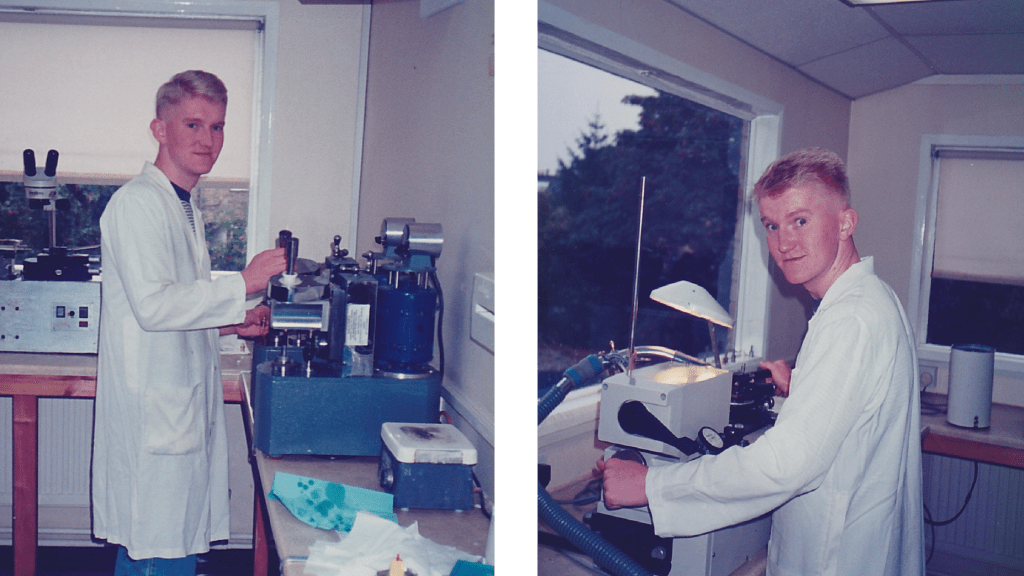

Gareth using lathes 30 years ago.